MACHINESHOP presents: TWAXIS

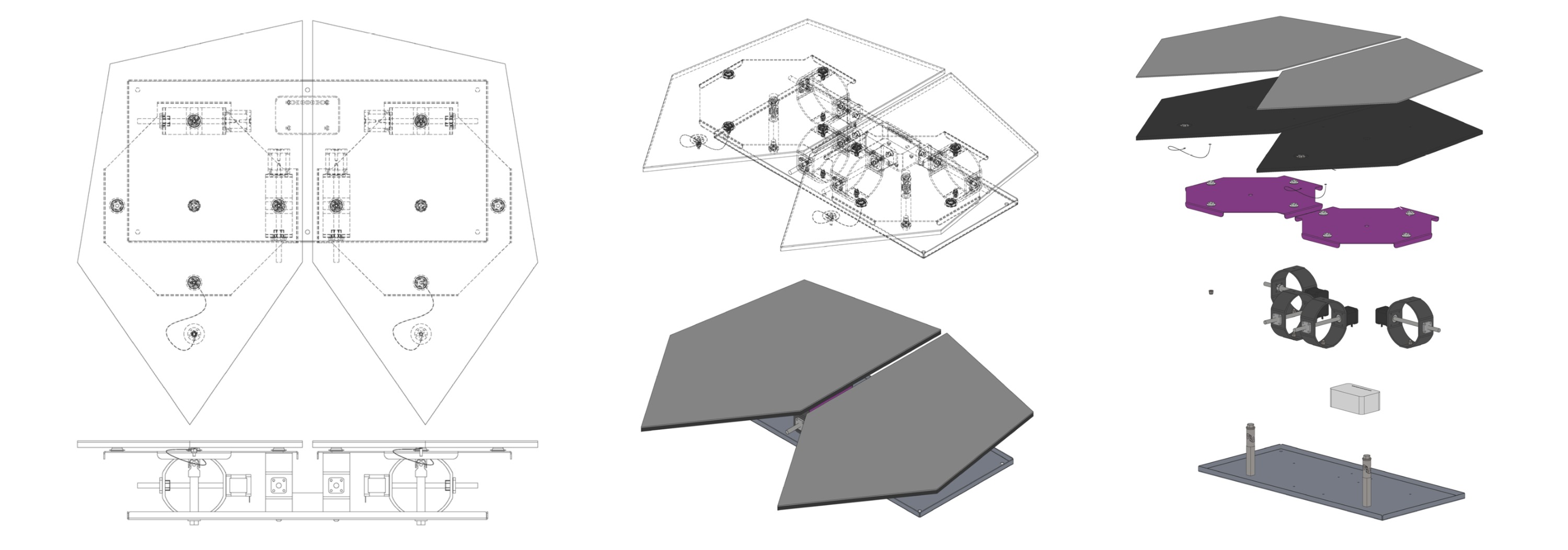

A silent, two axis, individually addressable gimbal system

Originally developed for installation on the MSC World Class Cruise Line

In response to a brief from MSC Cruises we developed a decorative ceiling feature to fill an organic shaped space on board their World Class cruise fleet. The brief called for originality, kinetic elements, and the high level of finish expected for a cruise ship. It also needed to be highly reliable with long service periods, almost totally silent, last at least 10 years of continuous service. Lastly, our solution had to compete on price with off the shelf products.

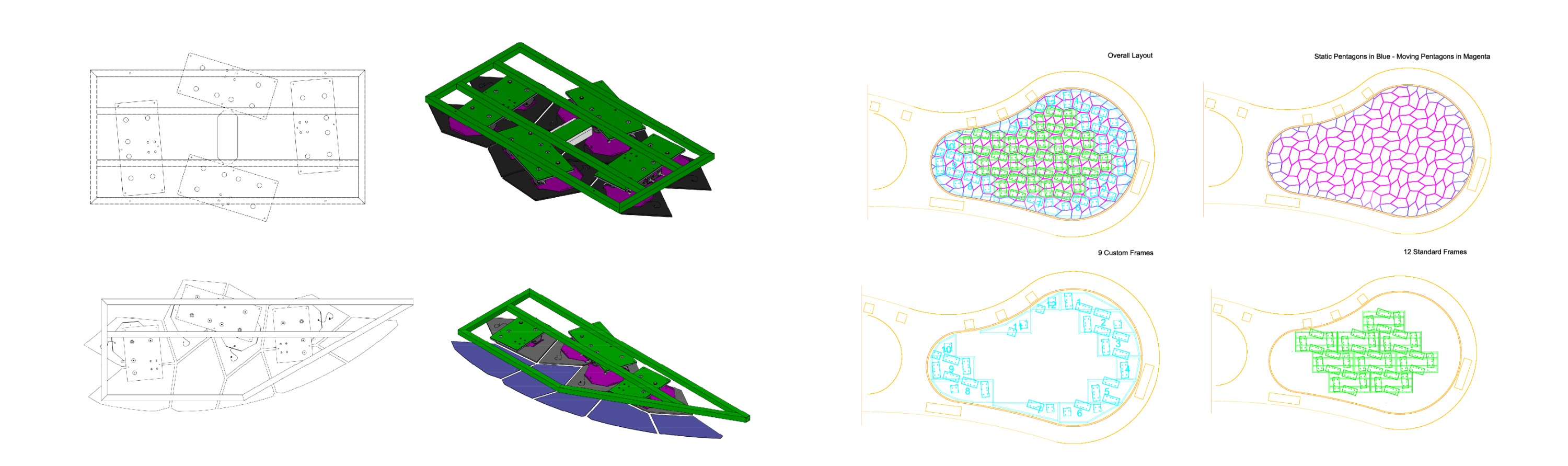

We designed a piece of software to fill the space with tessellating pentagons, and to animate the pentagons so they could tilt in two different directions. Through this design tool our client agreed upon a shape for the panels and a series of motions.

A traditional direct drive two axis gimbal. The geared motors not only produced a lot of noise but the backlash in the drive made it clear that very costly, high specification parts would be required. The use of traditional scissor mechanisms would require at least 6 bearing surfaces per axis, 12 per mirror!! A new concept was required.

The use of a compliant elastomer band enabled the number of bearing surfaces to be reduced to one per axis, two per panel The inherent resistance in the band eliminated the panel backlash. The use of a leadscrew provided accuracy and vastly eliminated noise.

Our TWAXIS gimbal mechanism is unique, the simplicity of the design permits reliability, silent operation and is highly cost effective. It is filed under UK Patent Application No. 2208713.4.

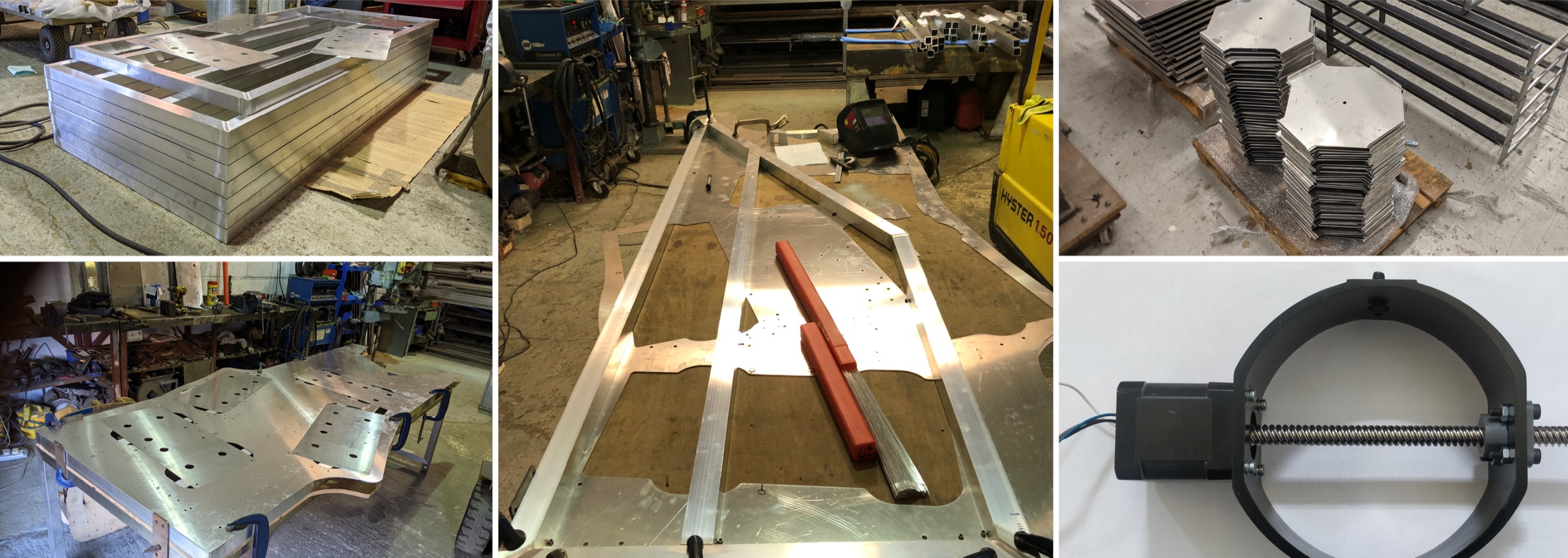

TWAXIS was built and assembled in the UK by MACHINESHOP before installation at Chantiers De l'Atlantique, Saint Nazaire, France. This arrangement for the MSC World Europa required a minimum of 120 gimbal units, plus a highly accurate mounting frame system.

Before the project could be installed onboard a full scale test was carried out, this was the first time in the process that more than 8 panels had been physically animated. In addition to the full scale test a longeivity test is running continuously for the foreseeable future to identify any future issues before they arise.

The Modular design of TWAXIS enables installation into organic spaces with limited access. Once the mounting framework had been installed onboard the rest of the project was entirely installed and built from compact cherry pickers.

TWAXIS: Behind the Scenes, a short film documenting the design, development and build and installation of this exciting project.